An online project under the direction of the CAPE ANN MUSEUM

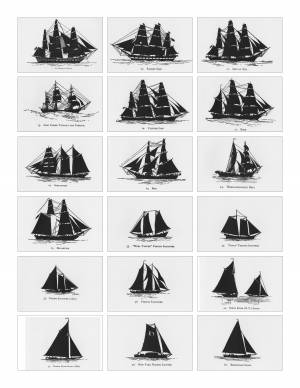

Vessel details: Rigging and Sails

Rigging and sailmaking are two separate businesses sharing many materials and fabrication methods, but kept physically apart by one substance and its application - tar. Sailmakers must be skilled in ropework, just as riggers must be with types of canvaswork that protects rope. But as tar is essential as a rigging preservative and used liberally in the rigging loft, its use in the sail loft is very limited and kept off the loft floor so as not to soil the sailcloth.

Sail lofts usually occupied the top floor of a large warehouse or wharf storage building whose truss frames required no supports from the loft floor, allowing a large sail to be laid out in whole (or in large part, if it was the mainsail of a large schooner). Rigging lofts also occupied top floors, but only floor length was critical; roof support posts were not an obstacle to layout or stretching. A stretching winch was necessary to both types of work; standing rigging cordage and boltropes alike required pre-stretching to avoid serious damage at sea.

– Erik Ronnberg

Related tables: Castine – Millard Dennett's Sail Loft »

Cape Ann Museum. Gift of Erik A.R. Ronnberg (2507.63)

A deadeye is a round block with scored holes for lanyards used to set tension on shrouds and stays. The upper deadeye is seized into an eye in the shroud or stay. The lower deadeye is fitted with a forged iron strap which is bolted to a chain plate fastened to the ship's hull.

Also filed under: Objects »

Also filed under: Castine – Millard Dennett's Sail Loft » // Historic Photographs »

Cotton fabric, hemp cord, iron draw-ring and thimbles

Cape Ann Museum (2507.62)

Riggers' ditty bags held an assortment of tools and materials for use outside the loft (at wharfside, on board, or aloft). Such items might include fids (for splicing), light cordage for whipping, marline and spunyarn for serving and seizings, needles and thread for canvasing rigging line at fraying surfaces. The items were selected according to anticipated tasks.

– Erik Ronnberg, as explained by Erik Ronnberg, Sr.

Also filed under: Objects »

Leather, rawhide, and steel

Cape Ann Museum (2726.2)

Worn on the hand to protect the palm when pushing a needle through tight-woven sailcloth. The eye of the needle sits in one of the dimples in the steel plate called the "eye."

Also filed under: Objects »

Steel and wood

31 in.

Cape Ann Museum. Gift of Erik A. R. Ronnberg, 1995 (2507.20)

A serving mallet is used to cover natural fiber rope with a wrapping of marline (or spun yarn). This covering would reduce chafe and keep water from getting into the cordage and causing rot. The marline would be applied with tar or tar would be added afterwards. This process would take place either in the rigging loft or on the vessel by a professional rigger.

View related Fitz Henry Lane catalog entries (1) »

Also filed under: Objects »

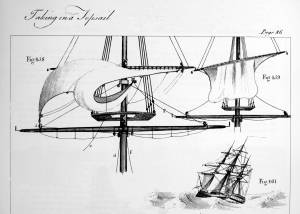

See figs. 458 and 459.

"In taking in a Topsail, Fig. 458, the Weather Sheet (f), is first clewed up, because the Sail naturally flies to leeward, and keeps full: then the Bowline (e), and lee Sheet (d), being let go, the Sail catches aback, like Figure 459, and is taken almost without a Shake; for if the lee Sheet were eased off first, the Sail might shake so violently as to split. However it is sometimes necessary when a Vessel is weakly manned, to haul the Clew-line a little up, in order to get the weather Brace in."

Reference:

Lever, The Young Sea Officer's Sheet Anchor or a Key to the Leading of Rigging and Practical Seamanship, 2nd ed. (1819), 86.